Note, this guide was never completed, but will update it at some point

Introduction

Here is my guide on how to make a 2.0 Zetec Blacktop fit into your Fiesta Mk3.5 16V. With no cutting and shutting to the engine bay. Dont know about you but thats the last thing i want to be doing!

Why you may want to fit a blacktop engine and to find out a little bit more about these engines is here

My install is a brand new blacktop engine, with no powersteering. If you wanted to fit a power steering pump you would have to retrofit it somehow, as its not the easiest thing to fit in, specially in a tight engine bay to start with.

Sorry if i write things that are obvious, there are people out there that are new to this and thinking about trying to give this a go. I was like that a long time ago and guides like this come in handy to newbies!

This is my parts/spec list:

- Brand new zetec blacktop 2.0 block

- Brand new zetec blacktop head

- 0.6mm Multi Layer Steel Elring headgasket

- Elring headbolts

- FAI Rs1800 headset

- Some spare inlet manifold gaskets

- Conti timing belt kit

- Ian Howels manual adjust timing belt pulley

- Unsure of who its made by but a 4-1 manifold and downpipe

- 130 Spec inlet manifold and throttle.

- Custom intake piping with closed KnN induction system.

- DEEP ecu (from mk1 mondeo (manual) can also use DEEP/DESK)

- Brand new Hella MAF

- Retaining my SI 16v thermostat housing/sensors.

The blacktop engine is very similar to the silvertop engine (basically just some internal mods/upgrades) and so as with the silvertop 2.0 conversion on a mk3.5 16V (ie with internal PATS (in ECU)), i can retain all of my standard wiring/sensors, apart from the MAF and ecu obviously. It will all just plug in.

A quick note on sumps for blacktop engines. The blacktop engines have two different lower sump and pickup pipe combinations, one for focus, and one for the mondeo (They ARE NOT mixable, you can use either on either, ie focus pickup and lower sump or mondeo pickup and lower sump. They will not physically fit if you mix them)

Make sure you do nuts and bolts up to the the correct torque rating. ESPECIALLY THE HEAD BOLTS!! Its important and can be the difference between dead or alive engine.

Although this guide is not yet complete, there will be a few sections. I suggest you read though them all (when i finish it!) before you start to take the challenge on, so you know what is involved!

Lastly, this is a guide, follow it at your own risk. If you decide to bodge something, its your own risk.

Part One – Bottom End Mods

Part One – Bottom End Mods

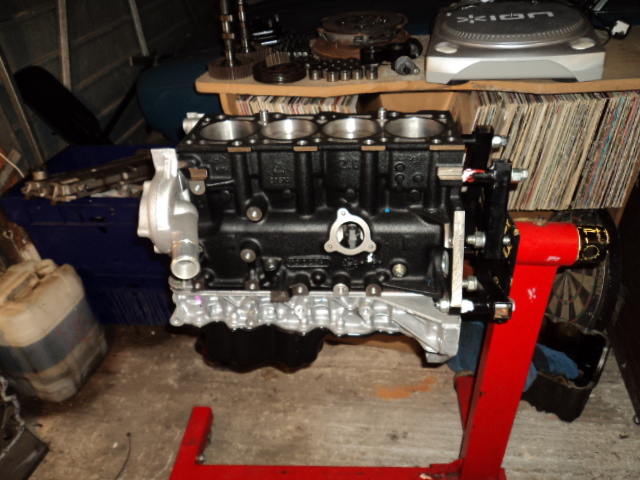

This is my new bottom end. Ive attached it too my stand, via the gearbox end, two bolts in the top bolt holes and nut and bolted on the two middle holes. Note – make sure you use decent bolts! Dont want in to fall off.

Turn the engine so its upside down, and you will be greeted with this:

Undo all 17 of the bolts with a 8mm socket.

Up next to tackle is the sump sealant:

Not sure what it is that ford use, but i would love to know. It sticks like sh*t to a blanket! You need to get the oil pan off the sump, best way i find is a small screwdriver and prise it open. Try not to bend the pan too much though!

Once its off, take off the pickup pipe. One 8mm bolt and two torx screws attaching it too the pump:

Nows a good time to make sure you remove all traces of gasket from the sealing surfaces.

Take out the 10 bolts holding the upper sump to the block with a 10mm socket. Remove it.

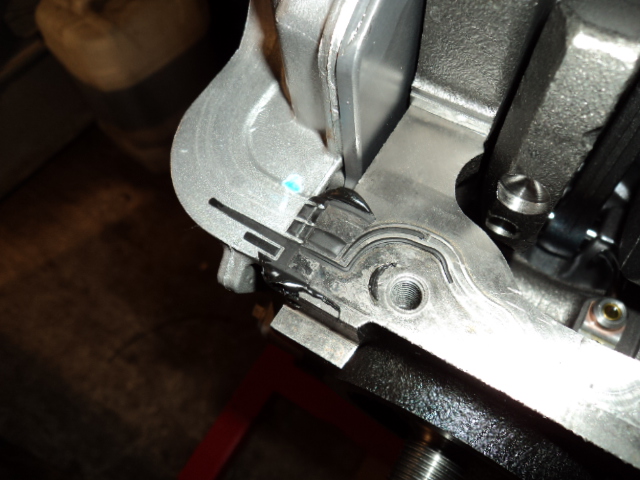

The upper sump needs to be modified. One so the starter will fit in. Two so the driveshaft wont foul it. Some comparison pics:

No easy way to do this, but get grinding! You can see how much ive had to take off, however when i did it for the first time i had to do a few mock ups before i got everything to fit nice. You may have to do the same too.

Nothing else to do this end of the engine so it can be put back together. Make sure you clean off any sealant left on the block and make sure its all nice and clean.

Usually it can just be rubbed away with your finger.

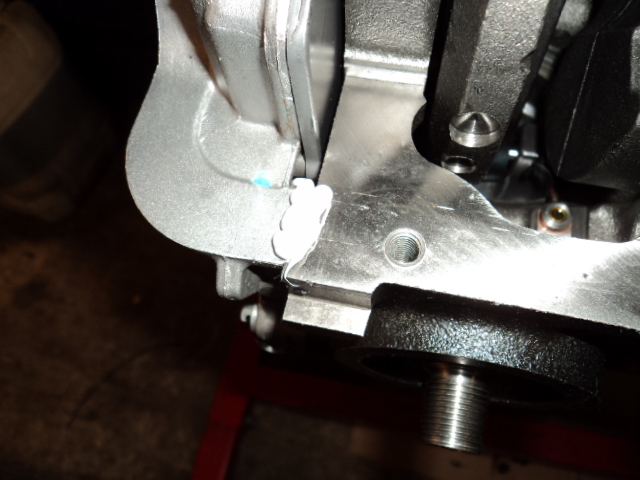

When refitting the upper sump, sealant needs to be applied to the corners where the oil pump meets the block and the oil seal carrier meets the block (Ford never seem to have done this but it says to in the Haynes manual):

Fit the new gasket into the upper sump and then onto the block. Tighten it down evenly and you will create a oil tight seal.

Next is to fit the pick-up pipe, apply sealant to the upper sump and fit the lower sump on top and tighten down evenly too create a oil tight seal.

Bottom end mods are comeplete!